Rubber Grommets NBR

A rubber grommet is inserted into a hole in a metal sheet to safeguard the passing electric wire which could otherwise wear down against the edge of the metal sheet. A bore with a diameter of d1 must be created in the metal sheet for the grommet.

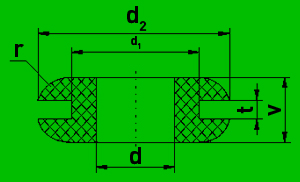

The grommets stated in the table follow the technical drawing below where the internal diameter of the grommet is d, and the thickness of the grommet is t.

Material for GUFERO rubber grommets

Rubber grommets are manufactured from high quality NBR (nitrile butadiene rubber). This material for grommets is characterized by its black colour. NBR rubber grommets are resistant to aliphatic hydrocarbons (e.g. propane, butane, petrol). In addition, these grommets are resistant to lubricants based on mineral oil. Using suitable grommets in conjunction with polar solvents and chlorinated hydrocarbons is not recommended. Grommets are also not resistant to ketones, benzols and esters either.

Temperature sensitivity of GUFERO rubber grommets

Grommets made of NBR may be exposed to temperatures within the range of -40 and +110 °C. If the grommets are to be exposed to steam the temperature range can increase to 130 °C.

Hardness of GUFERO rubber grommets

The NBR grommets are manufactured with a standard hardness ranging from 45 to 55 ShA. The hardness of rubber grommets with this range of ShA is measured by a durometer. The hardness of type A, which is not only used for rubber grommets, but also for other ranges of rubber articles is measured by the load applied to the tip of the gauge measuring the grommet using a weight of 0.822 kg. The measured distance by which the rubber grommet bends is indicated behind the measured hardness of the grommet. The actual value of the hardness of the rubber grommet is not a sign of quality. This is only an attribute to assist a designer or engineer to select the correct rubber grommets. In most cases the hardness is not the decisive factor for the selection of the rubber grommet. The purpose for which the rubber grommet is designed is the necessity to protect the cables running through the bore in the metal sheet. The hardness of the grommet is not important because the grommet itself is not subject to any direct pressure.

Products in category

Parametric searchFields irrelevant to your search leave empty.